Structure and operating principles of flexo printers

Main content

Flexo printers include many different parts: the input paper roll. color stations, the dryer between the color stations, the print cutters after finishing ...

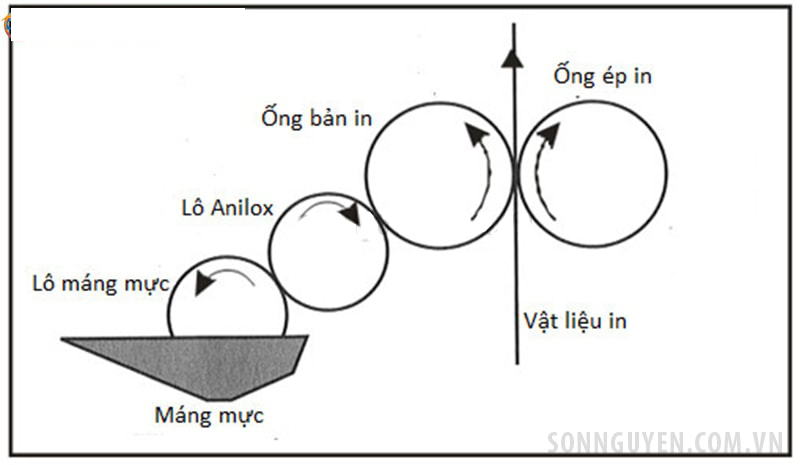

The most important element is the color stations, which is the part where the image is printed onto the media. Each color station consists of: rollers (circular batches): a fountain roller lot, an anilox roller plot, an anilox roller batch, a plate cylinder or plate cylinder and a media transfer batch. or an impression cylinder.

Or the color station can be divided into: Ink transfer system and printing system. In which, the ink transmission system (including ink tray batches and anilox batches) takes care of taking and transferring ink to the anilox, the printing system (including printing molds batches and printing media batches) takes on the task of printing images on the materials. print.

.png)

Parts of a color station

The ink transmission system of the Flexo printing

The system has a lot of ink troughs (a system of 3 ink transfusion lots), including: ink troughs, ink troughs, anilox lots.

3-batch ink transmission system

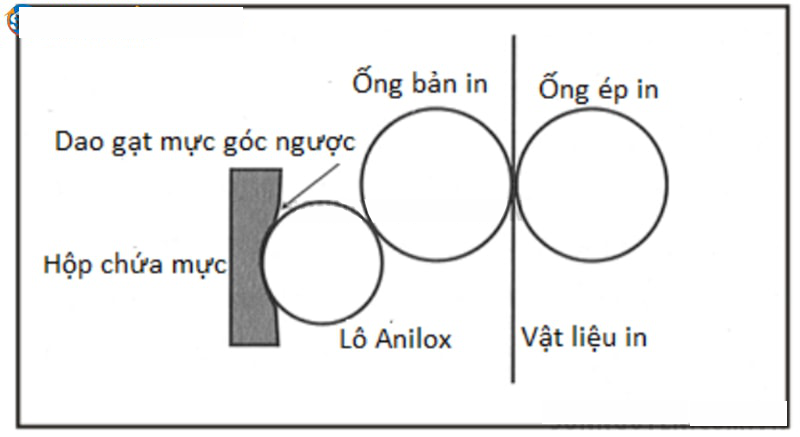

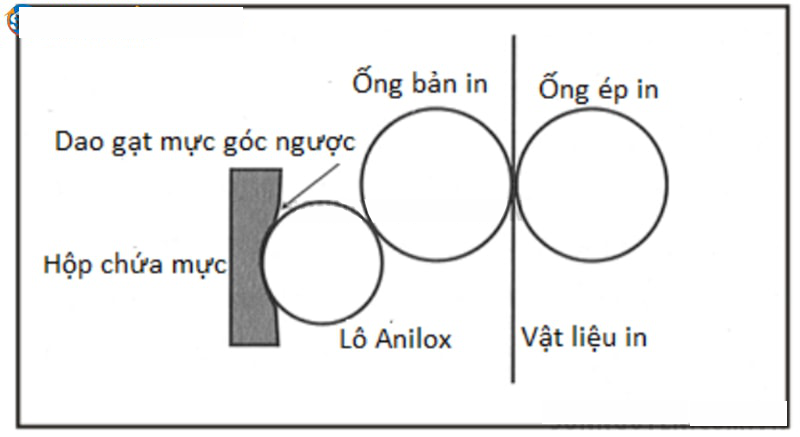

The system does not have a lot of ink troughs (the system of 2 ink transfusion lots) includes: ink trough, anilox batch and ink brush.

2-batch ink transfer system (open cartridge)

In which, the ink trough includes open type and sealed box. Both types use anilox batches - this is the most important part of the flexo printing method. During operation, the anilox batches are brushed off the ink on the surface of the batch by the knife system or rubber lot, leaving only the amount of ink in the small cells (cells) on the lot.

Principle of working inflexo machine system

Ink tray lot: (Fountain Roll)

Ink gutters are usually covered with a layer of natural rubber or synthetic rubber on the surface. This batch is fixed in the ink trough and rotates in it. It has the effect of absorbing ink from the ink tray to the batch, quantifying ink (anilox batch). It also has the function of cleaning ink on the anilox surface.

In case a Flexo printer does not have an ink tray batch, the anilox shaft will automatically shift to take the ink directly from the ink tray.

Anilox lot or ink measuring lot

Anilox plot is a cylindrical tube on the surface different from the small cells (Cell) containing ink, the ink volume in the cells contains the same amount of ink. Anilox block is made from metal such as steel or other alloy, the surface can be chrome plated or covered with ceramic (anti-oxidation).

Anilox batches have different length and diameter depending on the printer size. The cells on the surface of the anilox block have the function of storing ink to transmit onto the print tube. The Anilox lot is a core component of the ink infusion system. Choosing the right batch of anilox for the job is critical for successful Flexo printing.

There are many types of anilox batches suitable for different printing needs. Each has a different shape, size, arrangement, density (ink / inch). These factors depend on the type of ink used, the amount of ink to be transferred to the print, the substrate, the characteristics of the template, and the characteristics of the ink transfer system that is a two-batch or backpack-transfer system.

Anilox batch surface is small cells containing ink

Printed forms

Flexo printing molds are made of photopolymer plastic. The printing mold can be fabricated by photochemical method, CTP or laser etching, and then attached to the printing roller using double-sided tape or a magnetic field. The choice of the printing plate (thickness, hardness, number of layers) depends on the printed material (paper, carton or film).

In addition, to ensure that the ink just printed is not smudged, a dryer can be equipped after each ink station. When the media passes through a color station, the dryer between the color stations dries the ink completely. This dryer can use hot air, infrared or ultraviolet rays, depending on the ink used.

At Viet Dat we provide a full range of flexo printers, suitable for many different products, many different materials and sizes. We will calculate based on customers' requirements, use purposes will give customers the best machine solution and the most competitive price.