LOT ANILOX IN FLEXO PRINTERS

Main content

Anilox batch function in the flexo printer ink supply system

Of all printing methods, the ink transfer process is one of the most important factors, determining the printing process and quality of the printed sheet. The ink transmission system of flexo printing consists of two main types: the one with a batch and the one without. The system has lots of ink troughs including: ink troughs, ink troughs, anilox lots. The system does not have a lot of ink troughs including: ink troughs, anilox batches and ink scraper, in which, the ink troughs are open and closed boxes. Anilox batch is used in both types, which can be said to be the soul, the core component of the flexographic printing method. Flexo printing can be distinguished from other printing processes by its ink system. During operation, the anilox batches are brushed off the ink on the surface of the batch by the knife system or rubber lot, leaving only the amount of ink in the small cells (cells) on the lot.

The anilox batch has the most basic function of quantifying the ink transferred during printing, and it indicates the accuracy of the thickness, which determines the ink consistency, and uniformity. central to the process of innovation in flexographic printing. Laser engraved anilox batches allow the use of a wiper blade, creating a uniform image when printing the product and over a long period of time. Today flexo printing can compete with all printing processes, largely due to modern anilox batch technologies.

.png)

Figure 1: Two-batch ink supply system: ink tray lot and anilox plot

.png)

Figure 2: Ink supply system with a batch of open ink troughs: anilox batch and brush knife

.png)

.png)

Figure 3: Ink supply system with a batch of closed ink cartridges: anilox batch and a ink brush

Structure of anilox batch of inflexo machines

In terms of structure, the anilox plots are a cylindrical tube on the surface with small holes (Cell) containing ink, the ink volume at the small hole (cell) contains a uniform amount of ink and is calculated according to separate units. Anilox tubes are made from metal such as steel, or other alloy on the surface can be chrome plated or ceramic coated. Anilox batches have different length and diameter depending on the printer's size. On the surface of the anilox block, there are engraved small holes (cell) that store the ink to transmit onto the print. The ink vents consist of two main specifications, representing depth and openness, which are important for print quality, including background uniformity and sharpness of fill points in a layered image. The Anilox lot is a core component in the ink infusion system. Choosing the right batch of anilox for the job is critical for successful flexographic printing.

.png)

Figure 4: Anilox lot used in flexographic printing

The structure of anilox in reality is usually a round tube made of steel on the surface with engraved small holes in the shape of a tower, a tower, a cone ... chrome plated or covered with ceramic, arranged at an angle of 30o, 45o, 60o. Number of holes from 80-2000 holes / inch. These holes have different shapes, sizes and depths to hold different amounts of ink. Anilox plots are usually engraved either mechanically or by laser. After engraving, they are plated with copper and then chromed, or covered with ceramic to increase their hardness, increasing their service life. Basic features of anilox plot include the following parameters: Screen spacing; Cell width; Width of the cell at its lowest point; Cell wall top width or flat area on the surface of the plot (land); Cell depth; opening angle; The side wall top is depicted in Figure 6.

.png)

Figure 5: Parameters of the ink cells (cells)

.png)

.png)

Figure 6: Cells in reality

Basic types of cells per anilox plot

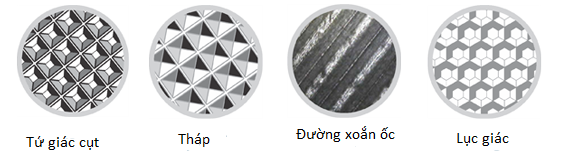

Anilox plots are engraved with a tiny container, which is usually an inverted pyramid shape. Anilox batches are of different sizes with different shapes of the containers. The basic shapes of the anilox plot cell are: pyramid and quadruple; hexagonal (hexagonal) or truncated hexagon (quad hex); spiral (trihelical line); channel picture (channelox).

.png)

Figure 7: Types of cell shapes on anilox plot

Pyramid shape.

Anilox batch with reversed pyramid-shaped cell is recommended for all flexo inks as well as varnish.

Quadrilateral shape truncated.

Anilox plots with truncated quadrilateral plots have more ink mass than inverted pyramid plots. These cells are often used with an inverted blade.

Hexagons and hexagons: This type has the same characteristics as a quadrilateral, but hexagons on the same area contain more cells.

Spiral shape.

Spiral batch type is used to apply high viscosity coating. This type of anilox batch can be used with or without a reverse angle knife.

Shape of connecting channel:

This type of plot can have different shapes, differing only on the surface between the plots with chanels connecting the plots for the purpose of facilitating the ink in and out of the plots during printing. .

3 color flexo printing machine | 4 color flexo printing machine | Prices for flexo printers